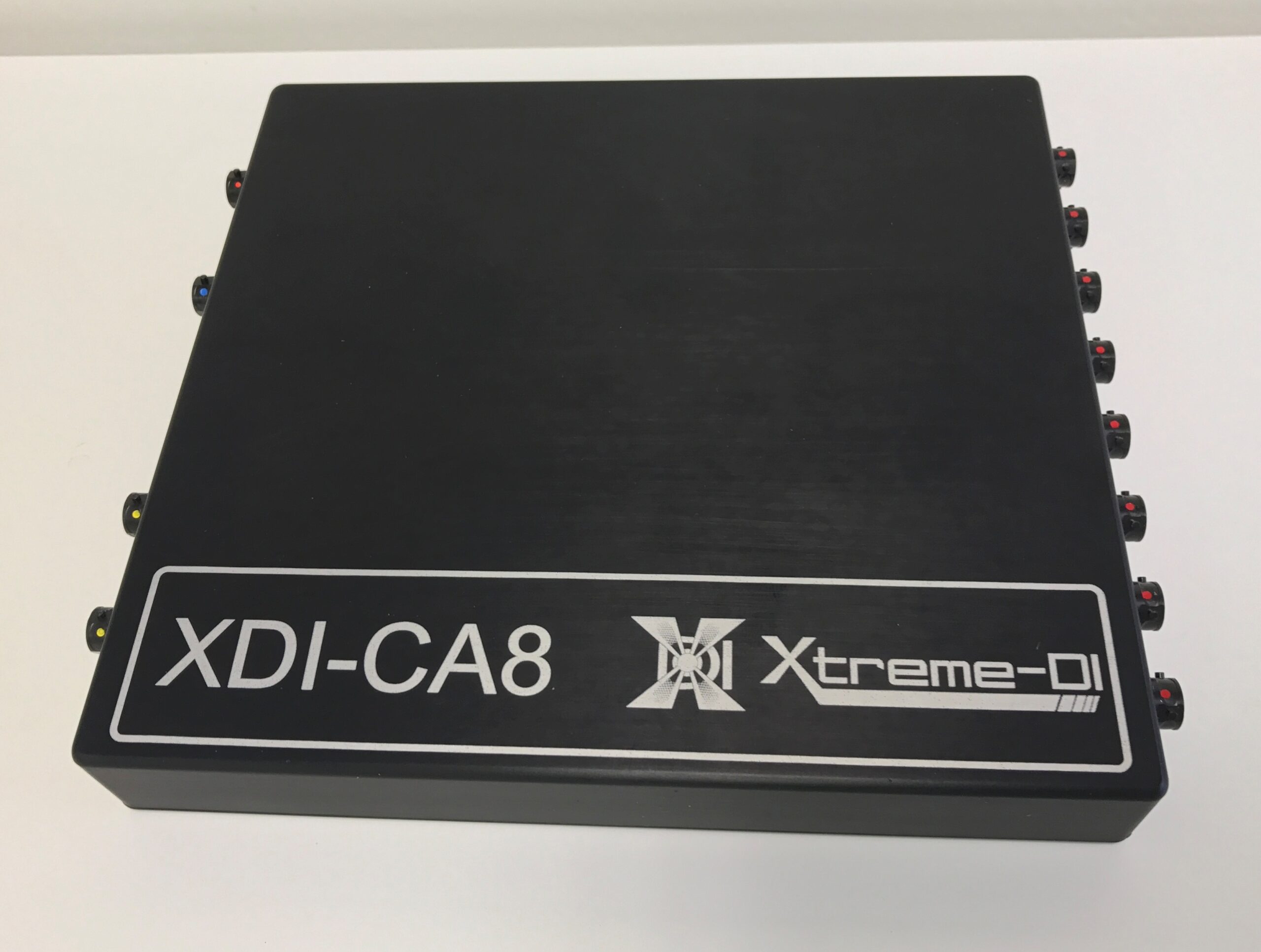

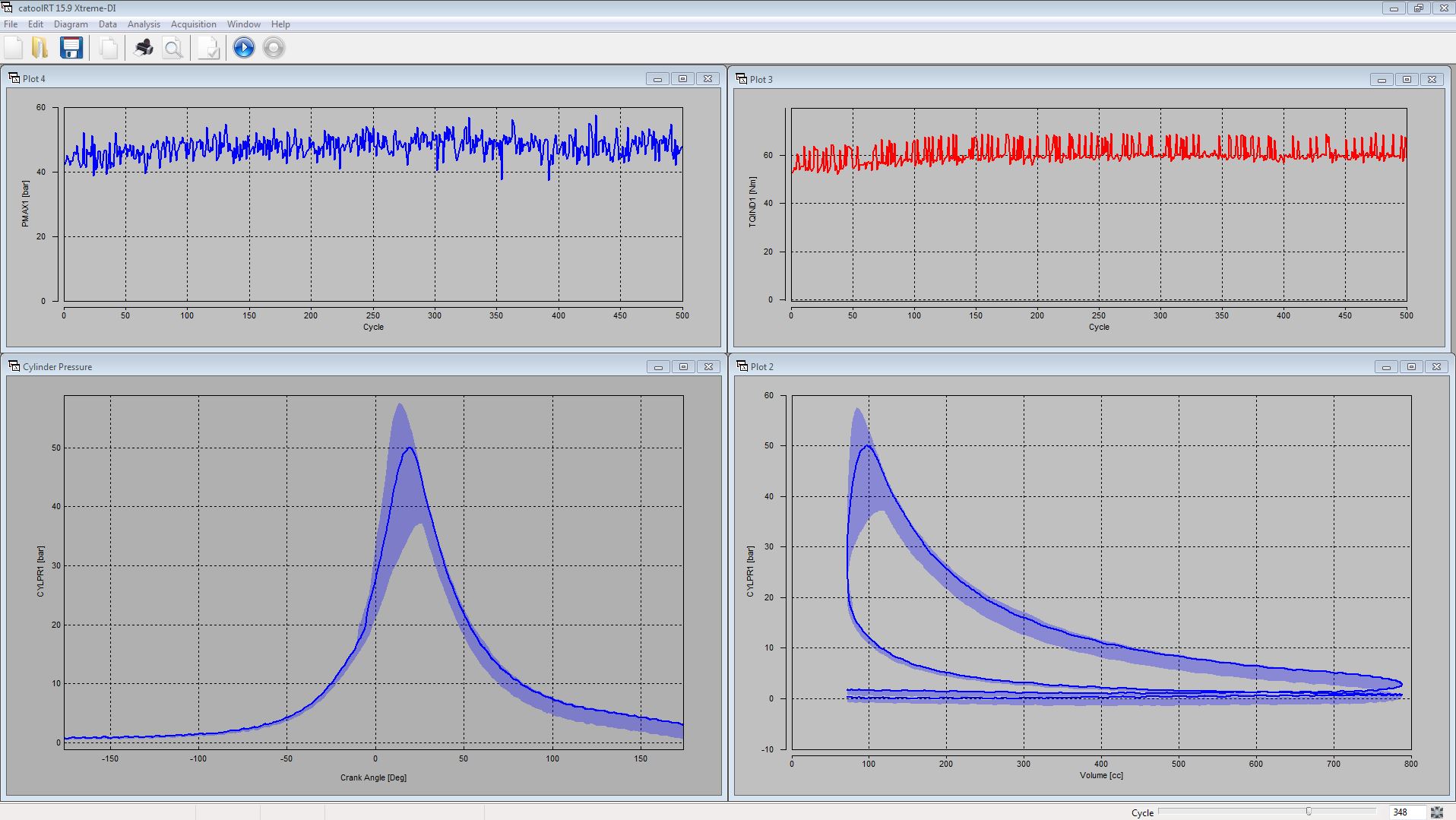

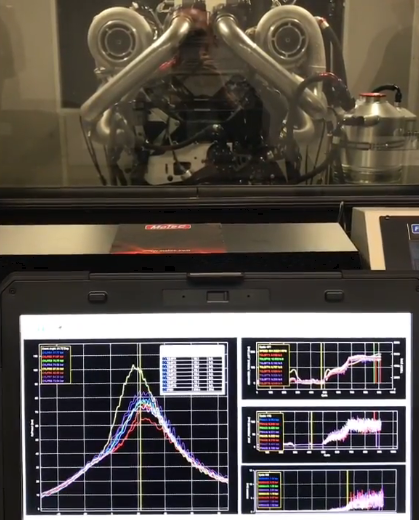

This combustion analyzer has specifically been designed for engine control and dyno monitoring applications. The design incorporates a data acquisition board with 8 high resolution inputs for pressure transducers or other inputs and 3 inputs for trigger signals (crankshaft hall, crankshaft VR, camshaft or encoder), all in a robust machined aluminum enclosure with mil-spec Deutsch ASU The analysis SW runs on every MS-Windows based PC or Tablet. For mobile use a preconfigured 10” Tablet is available on request. Speed Sensor Inputs: Transducer Inputs: Acquisition Rate: Sensor Type: Optimized for Fibre-Optic sensor type Housing Material: Housing Temperature Range: 0°C to 60°C ADC Resolution: 16bit Timing resolution: 10ns Weight: 730g CAN-Output: Kvaser Pressure Input Signal: -10 to +10 V Trigger Input Signal: -10 to +10 V Power Supply Voltage: 11 to 30 VDC, 30 W Connectors and Wires USB Connectivity: ASU05SB Pricing

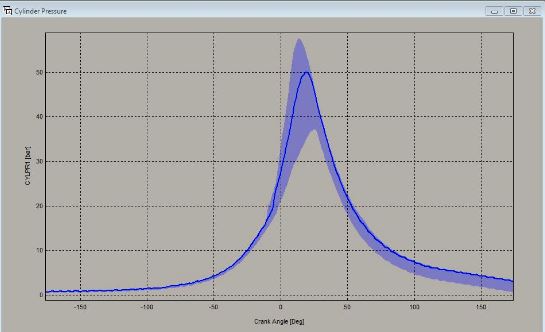

connectors. This robust design makes it resistant to vibration and high-temperatures. It features realtime dynamic pressure measurement of combustion or port pressure in spark-ignition or

compression ignition engines.

The cycle based pre-processed characteristics can be sent on CAN-bus in real time to be post processed in another ECU or recorded on a datalogger together with your engine and dyno data. Additional CAN-HW is necessary.

3 Inputs, shared Ground for hall type

VR sensors optional with integrated conditioner board

3600ppm encoder recommended

up to 12 Inputs, ±10V, pre-configured for XDI-CPS

100kHz per channel

1000kHz in single channel operation

3mm billet Aluminum

3D printed ABS-plastic

Optimized for Optrand Sensors, 0-5V

VR optional with integrated conditioner board

regular wall-outlet power supply with ASU connector is part of

the kit

CRK-Connector VR: ASU03SD

CAM / CRK-Connector ASU03SA

Sensor Connectors ASU03SN

integrated +5V supply, 1A total for all channels

12 sensor supply on request

Power Supply: ASU03SC

XDI-CA2 rp / billet $4,500 / $4,900

XDI-CA4 rp / billet $5,500 / $5,900

XDI-CA8 rp / billet $8,800 / $9,500

XDI-CA10 rp / billet $9,900 / $10,600

XDI-CA12 rp / billet $10,900 / $11,700

APPLICATION

2-12ch, CAN-output